In the process of continuous economic development, the level of urbanization continues to deepen, and the process of urbanization is accelerating, which has strongly promoted the development of China's construction industry. During the construction process, due to the changes in the building structure and overall building form, it has brought some difficulties to the construction of the project main body. Nowadays, with the rapid development of hollow plastic templates, various hollow plastic template companies have emerged in the market like mushrooms after rain, and the products they produce are diverse and the quality varies, which is daunting. So, as a newcomer to hollow plastic templates, how to determine the quality of a certain hollow plastic template?

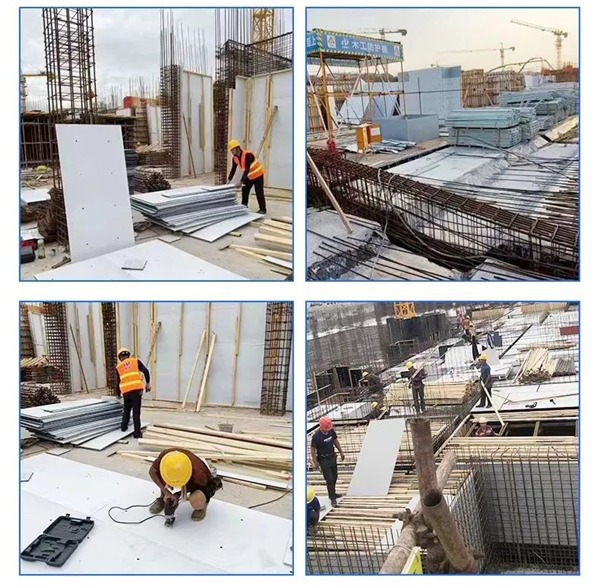

- Strength: In many promotional materials, a series of inspection report data will be listed, but these data cannot convince people of the real compressive strength and toughness of the hollow plastic template. We can try to use a hammer to knock the template or use a forklift or trailer to press the template. In order to further check its strength, it must be used once to obtain more reliable data. When to use it? How to evaluate its strength? This is easy. Use the hollow plastic template under the same building construction conditions as the wooden template for in-situ concrete testing, and finally achieve the actual forming effect, so as to intuitively prove the strength of the template, whether the wall has a wave shape, and whether it is flat and smooth is the most direct proof of the strength of the hollow plastic template.

- Does it deform at different temperatures: It is well known that the natural environment of construction sites is very complex and cannot be controlled. Weather factors are one of the important factors that interfere with the natural environment of the construction site. The template itself is also greatly affected by the weather. Good products are universal products that can adapt to various environmental conditions. Good hollow plastic templates are actually the same. According to an understanding of various hollow plastic templates on the market and discussions with construction site workers, it is known that many plastic templates nowadays will deform under high temperatures and unused conditions, which seriously affects the construction quality. Moreover, plastic templates deformed at high temperatures are also difficult to meet the requirements of building construction. Therefore, whether it deforms under high temperature (deformation will interfere with the structure of the building) is also one of the factors to evaluate the quality of the hollow plastic template. You can try boiling the hollow plastic template in water or freezing it in a refrigerator to see if the template will deform, in order to judge the quality of the template.

3. Characteristics of good plastic templates

• It can be turned over 50-100 times, and no additional mold is required for high-rise buildings. The usage cost is lower than that of traditional templates, effectively reducing project costs.

• It is produced according to the required size, and no on-site cutting is required, reducing material waste and saving labor costs.

• The template thickness has no positive and negative difference, and it has strong versatility. The splicing combination effect is smooth and flat.

• It has strong impact resistance, good toughness, wear resistance, acid and alkali resistance, and does not layer or bubble when soaked in water, and does not deform.

• It is light in weight, easy to process on site, can be nailed, sawed, and drilled, and can be connected in any direction.

• No need to brush the demolding agent, the demolding is easy, and the template can be easily removed by tapping it lightly, saving time and effort and accelerating the project progress.

• After the template is removed, the concrete surface is smooth and flat, and no secondary plastering is required.

• When choosing a template, only templates with the above characteristics can be considered good templates.